Clyde's Corner

Different Types of Pumps and How to Select One for Your Application

There are a multitude of different pumps that can be used depending on your water or wastewater application. It is critical to select the right pump based on the application to maintain efficiency and effectiveness.

Troubleshooting a Wastewater Control Panel: A Beginner's Guide

Wastewater control panels are essential components in the management and treatment of wastewater, ensuring that various processes in a treatment plant function smoothly and efficiently.

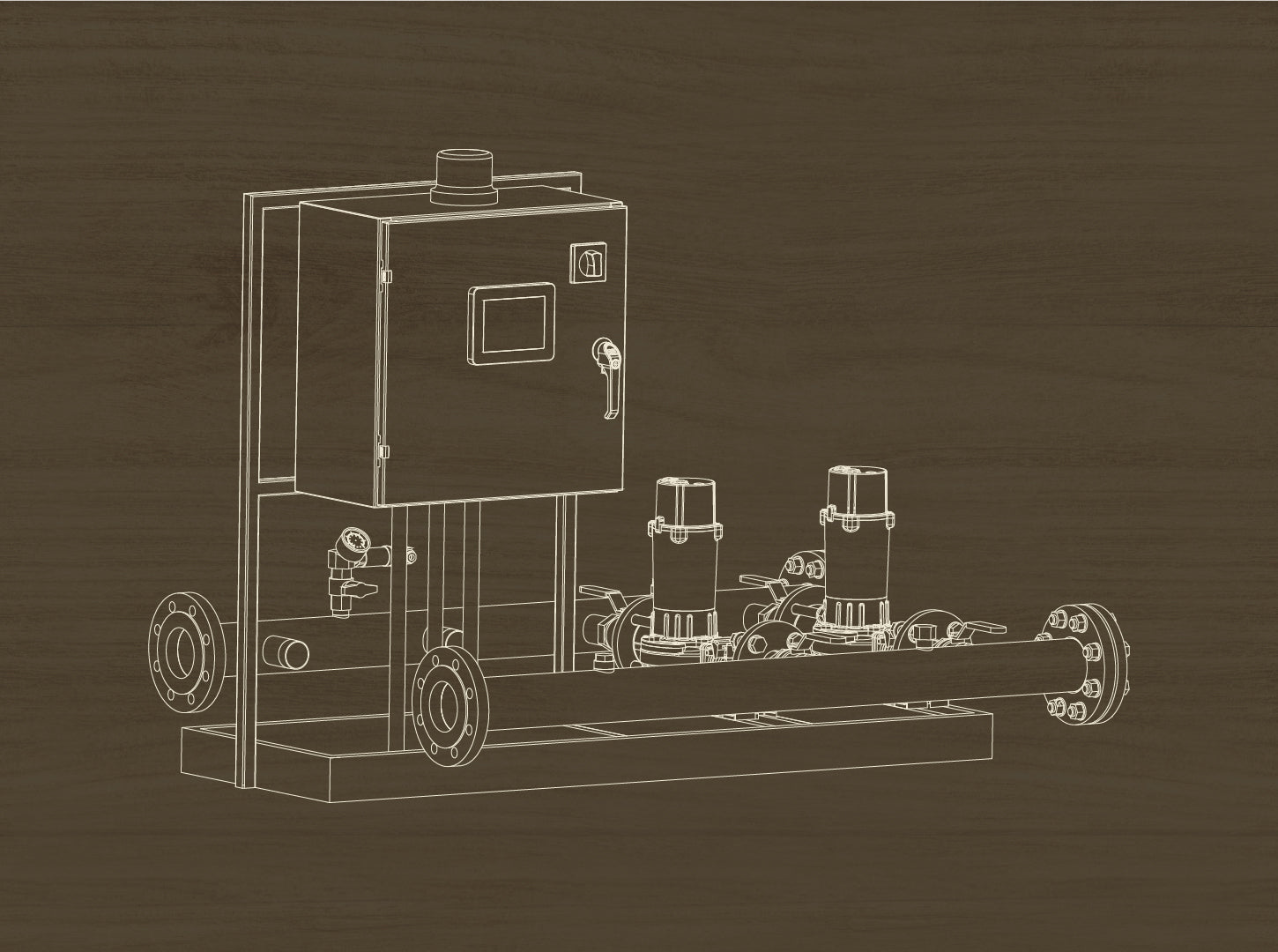

Constant Pressure Boosting System: The Basics

The goal of a constant pressure pumping system is to maintain desired water pressure wherever it is needed. These systems are critical to delivering water throughout society. Anywhere you might use water, there is a boosting system used in some way shape or form to deliver that water.

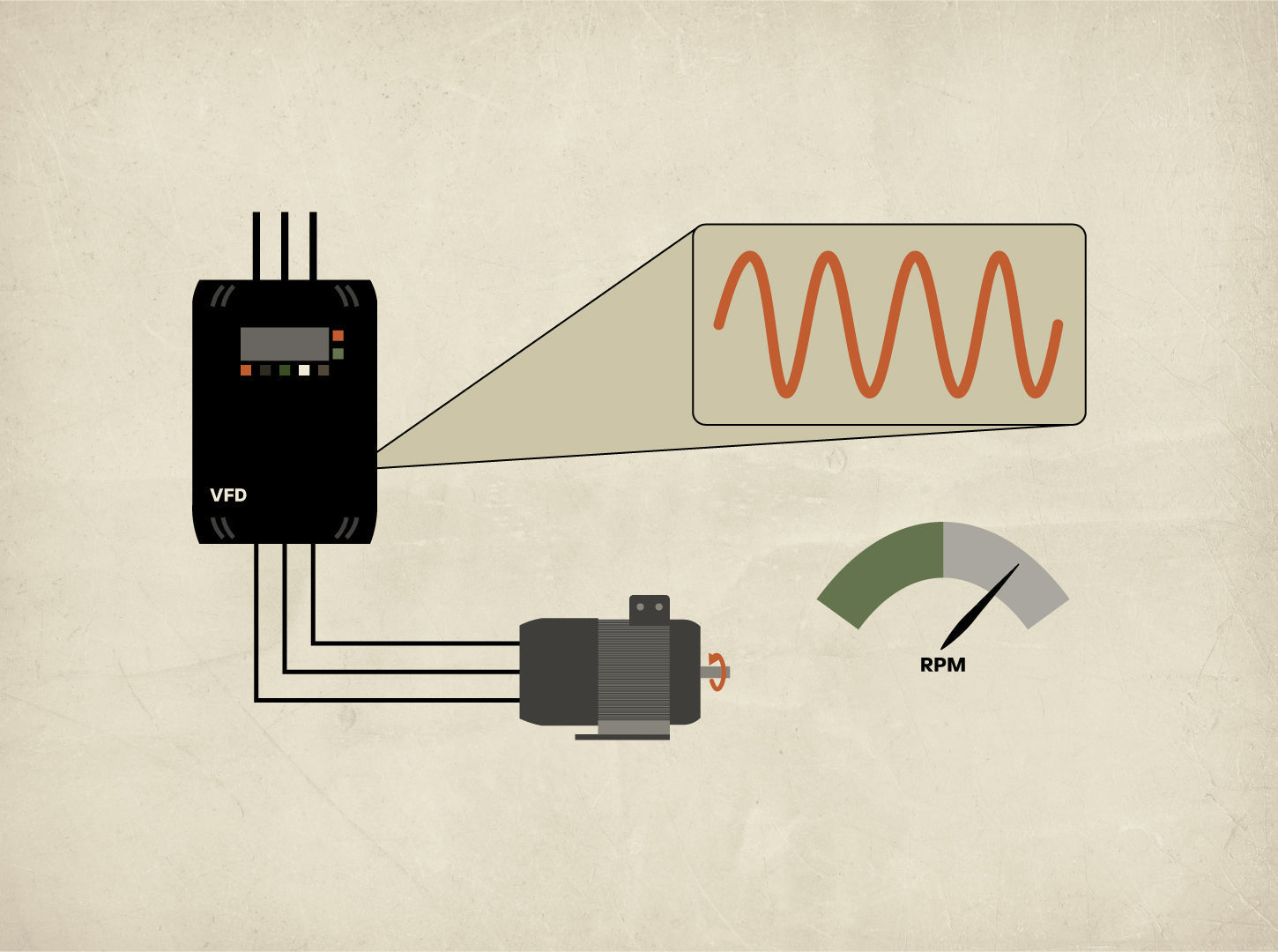

The Benefits of VFDs: Why Choose a Variable Frequency Drive Control Panel?

VFDs are very efficient in applications where the flow, density, and/or viscosity of the media may vary quite often because the pump speed can be controlled to match the variable demand of the media being pumped.

Top 8 Signs Your Pump Control Needs Maintenance

Let me guide you through the top signs your pump control panel needs maintenance — because nothing ruins a peaceful wilderness retreat like low water pressure when you're filling your favorite hollowed-out tree trunk with more water!

Quality control and quality assurance often referred to as “QC” and “QA” are critical steps in the manufacturing process that are used by businesses to guarantee a product has met the quality standards and requirements for a customer/client.

Pump control panels are vital for ensuring the efficient and reliable operation of water and wastewater systems. These control panels serve as the nerve center for managing the flow of liquids, automating processes, protecting equipment, and monitoring performance.

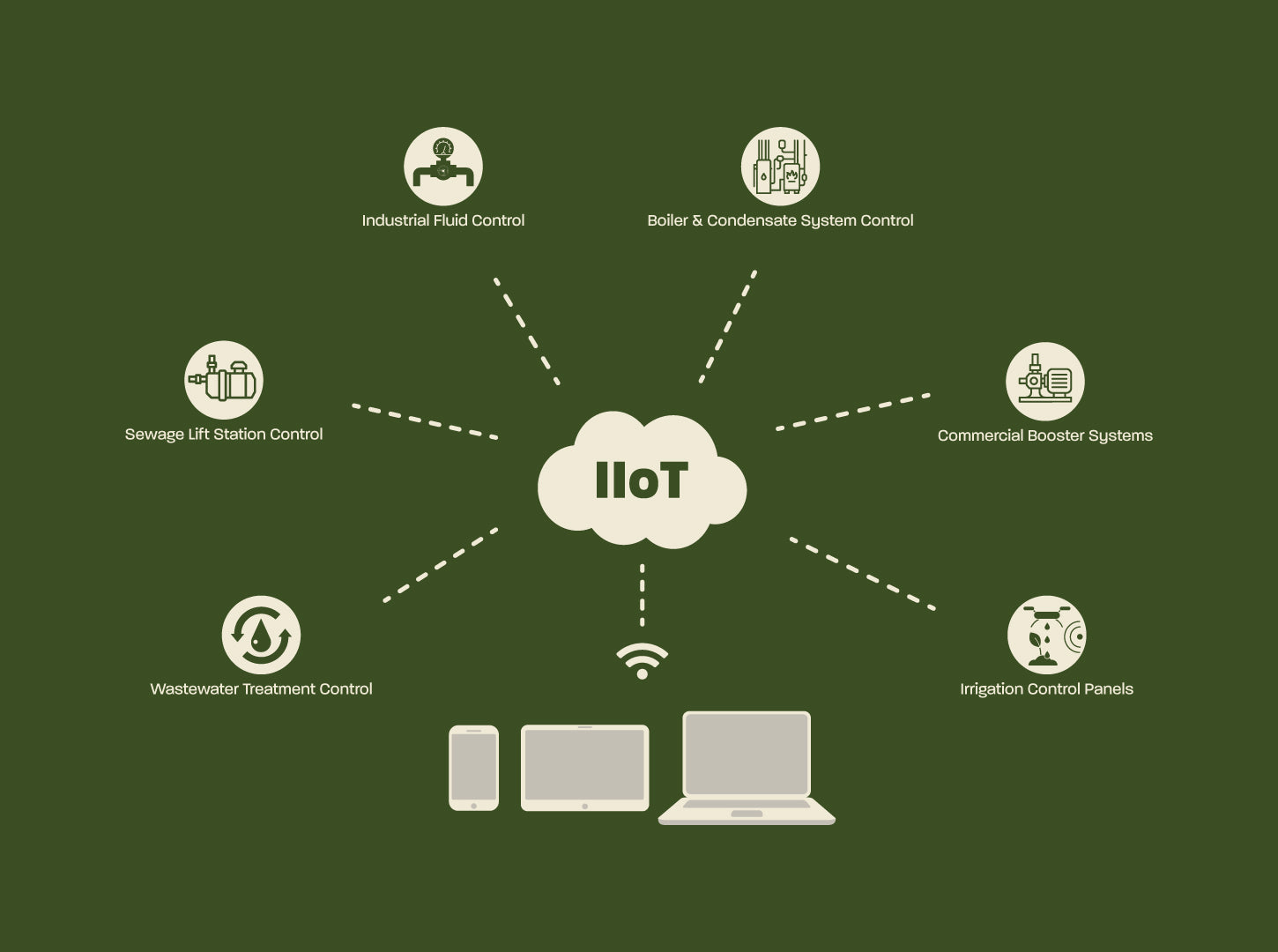

Using IIoT in the Pump Industry

The Industrial Internet of Things (IIoT) connects you to your pumps from anywhere in the world. IIoT enables remote monitoring, centralized control, and data insights for all of your pump stations.

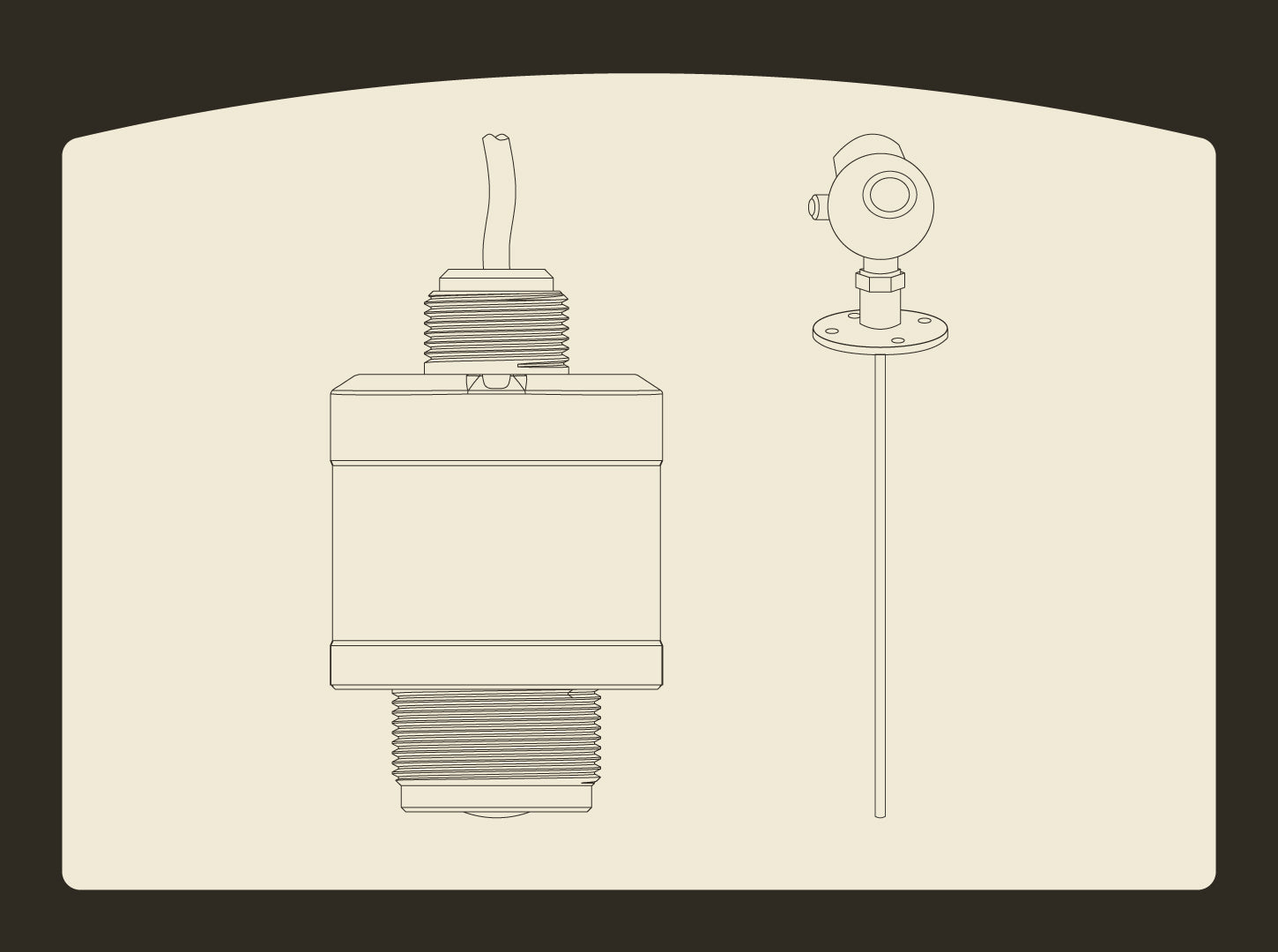

Radar sensors are among the most versatile and reliable level sensors on the market today, increasingly used in various applications within the water and wastewater industries.

Promoting Your Local Business Online: A Guide for Plumbers and Contractors

Without a web presence, you could be missing out on a huge opportunity to promote your plumbing or contracting business in front of new local customers. The good news is that you don't need to be a digital marketing expert to get started.

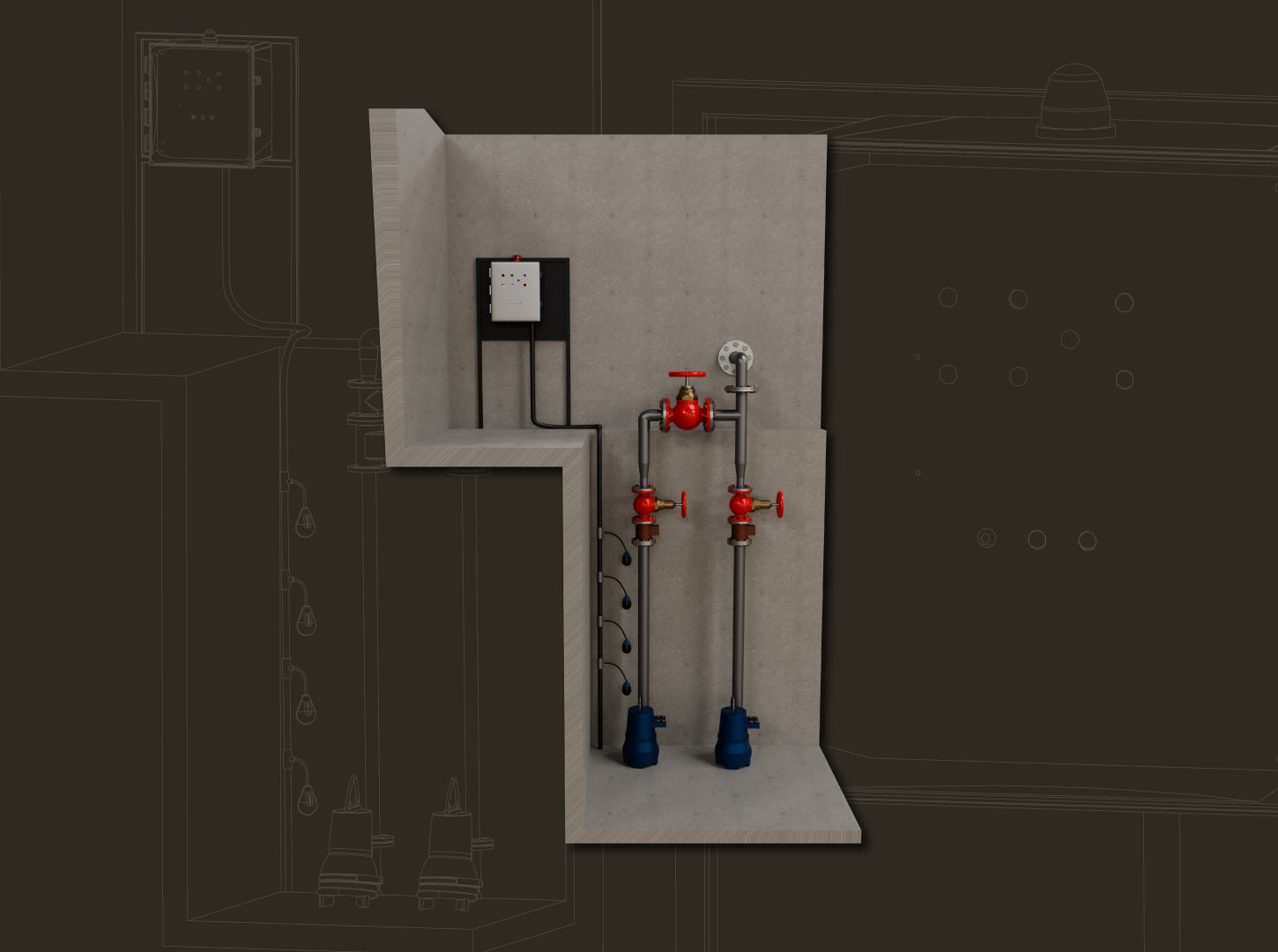

Understanding How Wastewater Lift Stations Work

Lift stations, or pump stations, are essential components of an effective sewage collection system and wastewater management systems. Their primary function is transporting wastewater from lower to higher elevations, mainly when there is insufficient gravity flow.

Understanding the Float Switch: A Comprehensive Guide