By Conrad Beattie

Last updated January 20, 2025

Constant Pressure Boosting System: The Basics

The goal of a constant pressure pumping system is to maintain desired water pressure wherever it is needed. These systems are critical to delivering water throughout society. Anywhere you might use water, there is a boosting system used in some way shape or form to deliver that water. The type of pressure boosting system needed will depend on the application. For example, the pressure boosting system configuration needed for a high rise building will vary greatly from a residential or municipal application. Some critical factors that will affect the selection of your pressure boosting system include water demand, system head, and desired pressure.

Types of Pressure Boosting Systems

Direct Boosting Systems: (Commercial, Industrial, and Municipal Applications)

In this system booster pumps are connected directly in-line with the main water utility connection, typically providing pressure to floors where water pressure is insufficient without the assistance of booster pumps. Direct boosting systems are the most common type of pressure boosting system.

Zone Divided Systems: (Commercial)

In this system, several sets of booster pumps are connected to the water main and maintain pressure based on a zone. For example, floors 5-8 of a building might be serviced by booster set A. While floors 9-12 might be serviced by booster set B. Zone divided systems are typically only used in high rise buildings.

Pressure Boosting Packages

Analog Systems (Advanced):

In advanced systems, a variable frequency drive (VFD) is used to manage the power delivered to the booster pump. The amount of power delivered to the pump will depend on the feedback from an in-line pressure transducer. Using the feedback from this sensor coupled with the advanced programming of modern drives and programmable logic controllers, a VFD-operated pump can maintain a pressure setpoint with very little over or undershoot. Advanced systems are used anytime there is little to no room for water pressure fluctuations and can prevent water hammering. Water hammering can occur when water within a piping system comes to an abrupt stop which can result in pressure spikes that risk damaging the pipes within the system.

Digital Systems (Basic):

In basic systems, a simple contactor is used to provide power to the pump. With a contactor, there is no modulation of power, the pump is simply on or off. Additionally, rather than using a pressure transducer, basic systems will typically use a pressure switch. A pressure switch will open or close an electric contact when the in-line pressure drops above or below the rating of the switch. These basic systems are cost-effective when maintaining a simple pressure level in applications that aren't as sensitive to pressure fluctuations. You might see this type of system used in a residential application with smaller pumps below 5 horsepower.

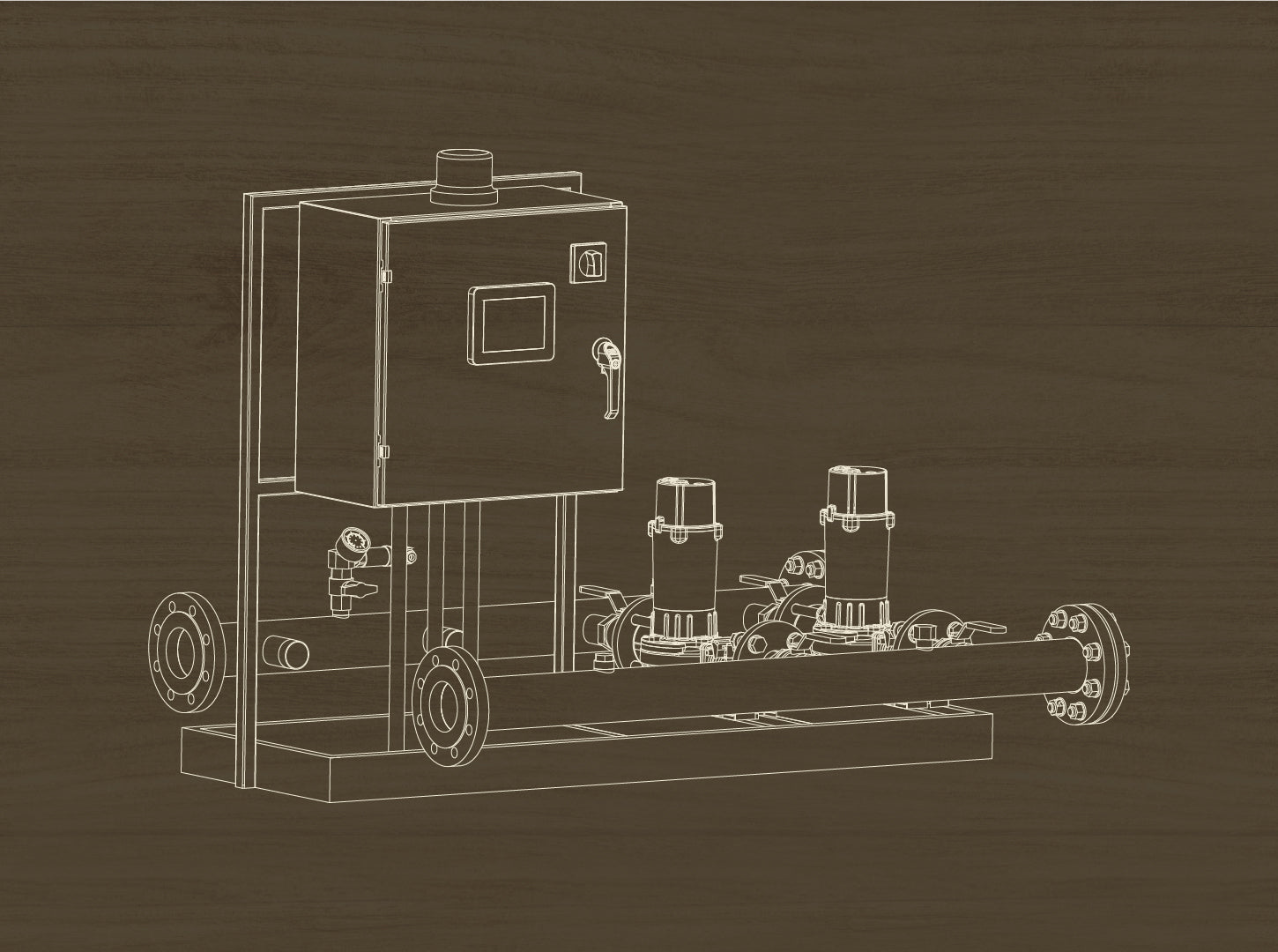

Components of a Typical Constant Pressure Boosting System

- Control Panel: The control panel in pressure boosting systems plays a critical role in the operation and management of the pumps. It typically provides electrical protection, monitors pressure sensing devices, and provides notification of pump malfunctions or high/low pressure conditions.

- Pumps: Pressure boosting pumps are typically installed in their own dedicated room or housing and are rarely submersible. These pumps often come on a pre-assembled skid as well. Pressure boosting pumps can be submersible, however it is rare. Pumps can vary greatly in size depending on the pressure required, as well as how much Total Dynamic Head the pumps will need to overcome.

- Pressure Transducer/Switch: Devices that measure pressure in the water line. These devices are critical to actuating a pump when necessary to maintain pressure

- Check Valves: Prevents the backflow of water, especially critical in systems that have significant pumping head.

- Bladder Tank: A supplemental tank placed in the water line, designed to absorb and disperse water when needed to help maintain pressure within the water line. The primary function of the bladder tank is to prevent the short cycling of a pump.

The Role of Variable Frequency Drives in a Pressure Boosting System

Variable Frequency Drives, commonly referred to as “VFD’s” are devices with advanced power electronics that facilitate the modulation of power to pumps and motors. This modulation of power impacts the speed at which a pump's impeller will rotate and subsequently allows for the precise control of a pump's flow rate.

In an advanced pressure boosting system, an in-line pressure transducer is often used to provide feedback on the active water pressure in the system. These systems aim to maintain a user defined pressure, or flow rate set point.

When the pressure reading drops, a VFD will increase power delivered to the pump to increase its operational speed, therefore increasing the pressure in the system. Through continuous closed loop control, a constant pressure pumping system with VFD’s can maintain PSI with very minimal over or underpressure.

Conclusion

Though there are many types of pressure boosting water systems, the end goal is always the same, to maintain pressure within a pipe. Without pressure boosting systems, it would be impossible to deliver water throughout society to the many outlets where it is needed.

Share:

The Benefits of VFDs: Why Choose a Variable Frequency Drive Control Panel?

Troubleshooting a Wastewater Control Panel: A Beginner's Guide