By Jesse Goldade

Last updated February 7, 2025

Understanding How Wastewater Lift Stations Work

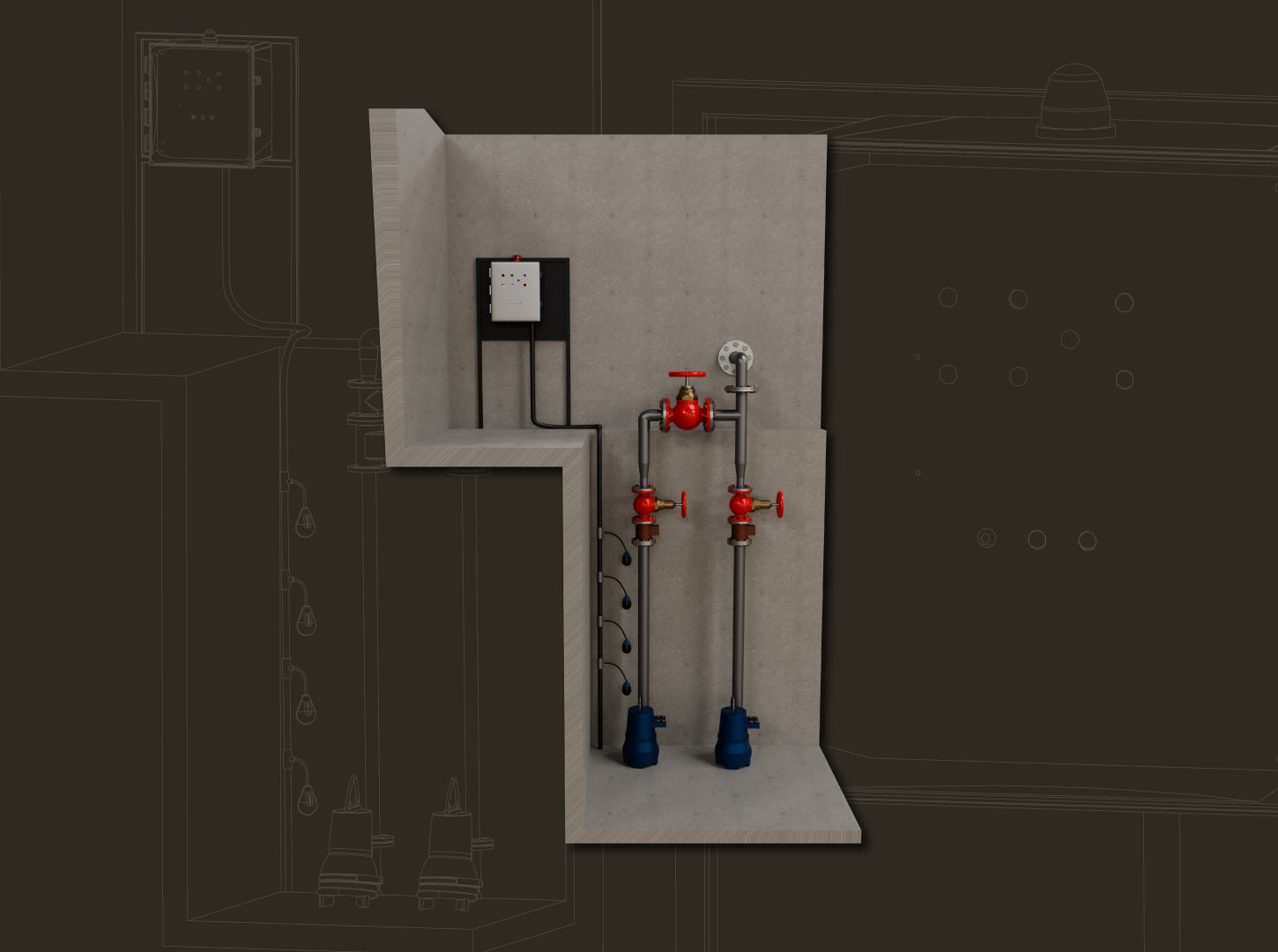

Lift stations, or pump stations, are essential components of an effective sewage collection system and wastewater management systems. Their primary function is transporting wastewater from lower to higher elevations, mainly when there is insufficient gravity flow. Most lift stations are designed in a duplex configuration; duplex control panels allow for equal wear on the pumps and the ability to have a backup pump if a motor fails or routine servicing.

In this article, we’ll cover lift station components, operations, and maintenance, and how to understand their role in modern infrastructure.

Components of a Lift Station

A typical lift station consists of several key components:

- Control Panel: The control panel in a lift station is a critical component that manages and monitors the operation of the pumps and level instruments (floats, transducers, radar, etc.) to move wastewater and or stormwater from lower to higher elevations. The control panel also manages lift station alarms, which notify operators of operational issues or equipment malfunctions.

- Pumps: Submersible pumps or dry-pit pumps, also known as lift station pumps, lift wastewater from the wet well to a higher elevation. Submersible pumps are submerged in the wastewater, while dry-pit pumps are in a separate, dry chamber.

- Wet Well: This is a basin where wastewater and stormwater are collected. It’s typically constructed from concrete, fiberglass, or polyethylene. The wet well is equipped with sensors to monitor the wastewater level.

- Valves: Check valves and gate valves to control the flow of wastewater and prevent backflow. Check valves allow flow in one direction, while gate valves can isolate a section of the system for maintenance.

- Discharge Pipe: This pipe carries the lifted wastewater to a higher elevation where it can continue to flow by gravity to the treatment plant or another lift station.

How Lift Stations Operate

The operation of a lift station can be summarized in the following steps:

- Collection: Wastewater flows by gravity into the wet well, which is part of the larger gravity pipeline system.

- Monitoring: Sensors in the wet well continuously monitor the water level. The control panel activates the pumps when the level reaches a predetermined point or time schedule. This can be achieved by utilizing floats, a transducer, an ultrasonic sensor, or many other instruments. Along with activating the pump(s), the sensors will also notify in the case of a high-liquid alarm, pump failure, power failure, or many other technical issues.

- Pumping: The activated pumps lift the wastewater from the wet well into the discharge pipe, utilizing a pressurized sewer force to move the wastewater to a higher elevation. Depending on the design, the system may use one or multiple pumps, which can operate in parallel or lead-lag configuration to handle varying flow rates and provide redundancy.

- Transport: The wastewater is transported through the discharge pipe to a higher elevation where it can continue to flow by gravity. The wastewater may sometimes be pumped to another lift station for further elevation changes.

- Deactivation: Once the water level in the wet well drops to a lower set point, the control system deactivates the pumps, and the cycle repeats. Ensuring the pump capacity matches the quantity of wastewater is crucial to prevent prolonged storage and maintain efficient operation.

Types of Lift Stations

There are two primary types of lift stations:

- Submersible Pump Lift Station: In this type, the pumps are submerged in the wet well, which contains the sewage. The submersible pumps are designed to operate underwater and are generally more compact and quieter than dry well pumps. The system may include a pressurized sewer force main to ensure efficient transportation of wastewater to higher elevations. This setup is often preferred for its simplicity and lower initial cost.

- Dry Well Lift Station: This type of lift station has the pumps and controls housed in a separate, dry chamber. The dry well is typically located adjacent to the wet well, where the sewage is collected. This design allows for easier maintenance and repair of the pumps and controls.

Submersible Pump Lift Station

- Design:

- The pumps and motors are submerged in the wastewater.

- The entire unit, including the pump, is placed inside a wet well.

- The submersible pump lift station is designed for efficient wastewater lift from the wet well to higher elevations.

- Installation and Maintenance:

- Easier to install due to fewer components above ground.

- Maintenance can be more challenging because the pumps are submerged, requiring the removal of the pump for service.

- Advantages:

- Quieter operation since the pump is underwater.

- Often more space-efficient as most components are below ground.

- Less susceptible to flooding because the electrical components are sealed and submerged.

- Disadvantages:

- More difficult and potentially hazardous maintenance due to the need to handle submerged equipment.

- Pumps are exposed to the corrosive and abrasive environment of the wastewater.

Dry-Pit Pump Lift Station

- Design:

- The pumps are located in a separate dry chamber (dry pit) adjacent to the wet well where the wastewater is collected.

- Dry-pit pump lift stations are a type of wastewater lift stations where the pumps are located in a separate dry chamber.

- The pumps are not submerged but connected to the wet well by suction pipes.

- Installation and Maintenance:

- More complex installation due to the need for a separate dry chamber.

- Easier maintenance as pumps and motors are accessible without removing them from the wastewater.

- Advantages:

- Maintenance is safer and more convenient since the equipment is dry and accessible.

- Equipment is less exposed to the harsh environment of wastewater, potentially extending the lifespan.

- Disadvantages:

- More expensive and complex to construct due to the need for separate wet and dry wells.

- More space is required to accommodate the separate chambers.

- Can be noisier since the pumps are not submerged.

Routine Maintenance of Lift Stations

Proper maintenance is crucial to ensure the lift station’s efficient and reliable operation. Routine maintenance is crucial to ensure the lift station’s efficient and reliable operation. Key maintenance activities include:

- Regular Inspections: Conduct visual inspections of the wet well, pumps, valves, and control systems to identify any signs of wear or damage.

- Pump Maintenance: Perform routine maintenance on lift station pumps, including cleaning, lubrication, and replacing worn parts.

- Control Panel: Inspect the panel for signs of corrosion, moisture, or physical damage. Ensure all electrical connections are properly sealed per the enclosure’s NEMA rating. Measure and record voltage and current to ensure they are within acceptable ranges.

- Float Switches and Sensors: Test and calibrate float switches and level sensors to ensure accurate readings and proper control of the pumps.

- Testing Alarm Systems: Regularly test alarm systems to ensure they function correctly and provide timely alerts in case of issues.

- Valve Maintenance: Inspect and maintain valves to ensure they operate correctly and prevent backflow.

- Cleaning: Periodically clean the wet well to remove debris and sediment that can accumulate and hinder pump performance.

Conclusion

Lift stations are vital components in sewage collection systems and wastewater management systems, enabling wastewater transportation from lower to higher elevations when gravity alone is insufficient. Using lift stations within a gravity pipeline system saves substantial excavation costs without compromising efficiency. Understanding their components, operations, and maintenance requirements is essential for ensuring their efficient and reliable operation. Lift stations ensure the continuous, safe transport of wastewater to the wastewater treatment plant for treatment and recirculation. By keeping these systems well-maintained, municipalities and utilities can prevent costly failures and ensure the continuous, safe transport of wastewater to treatment facilities.

References

- "Lift Station Basics," U.S. Environmental Protection Agency (EPA)

- "Pumping Stations in Wastewater Collection Systems," Water Environment Federation (WEF)

- "Wastewater Pumping Systems," American Water Works Association (AWWA)

- Submersible Sewage Pumping Systems (SWPA) Handbook, Fourth Edition

Share:

Understanding the Float Switch: A Comprehensive Guide

Promoting Your Local Business Online: A Guide for Plumbers and Contractors