Troubleshooting a Wastewater Control Panel: A Beginner's Guide

By Brandon Rugh

Last updated March 12, 2025

Troubleshooting a Wastewater Control Panel: A Beginner's Guide

Wastewater control panels are essential components in the management and treatment of wastewater, ensuring that various processes in a treatment plant function smoothly and efficiently. These control panels house electrical components and programming systems that monitor and control pumps, valves, sensors, and other critical devices in the system. However, like any electronic equipment, wastewater control panels can experience malfunctions or failures, requiring troubleshooting to identify and resolve the issue.

In this article, we’ll break down the basics of troubleshooting a wastewater control panel, covering essential steps to take, potential problems, and tips for ensuring optimal operation.

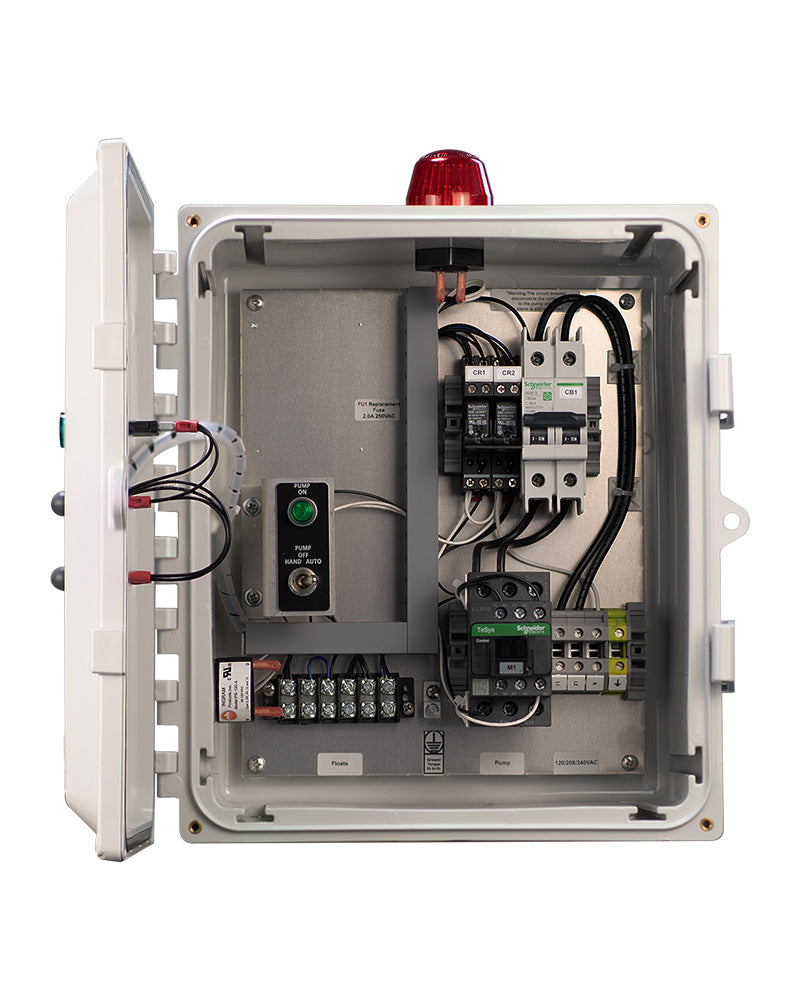

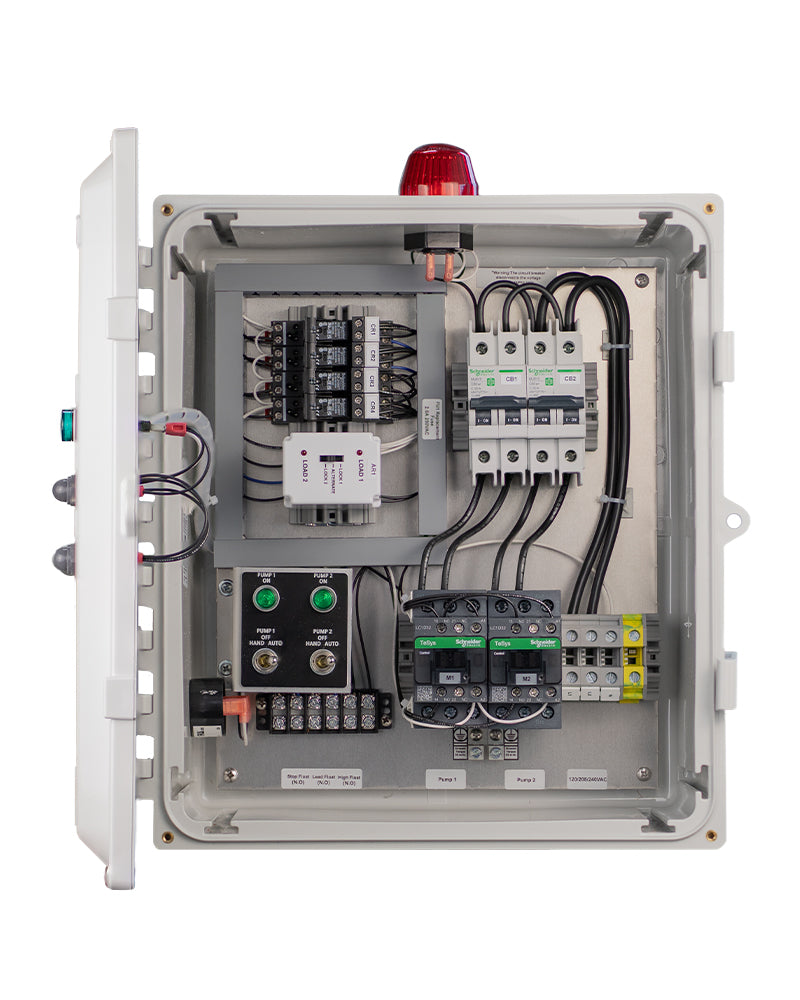

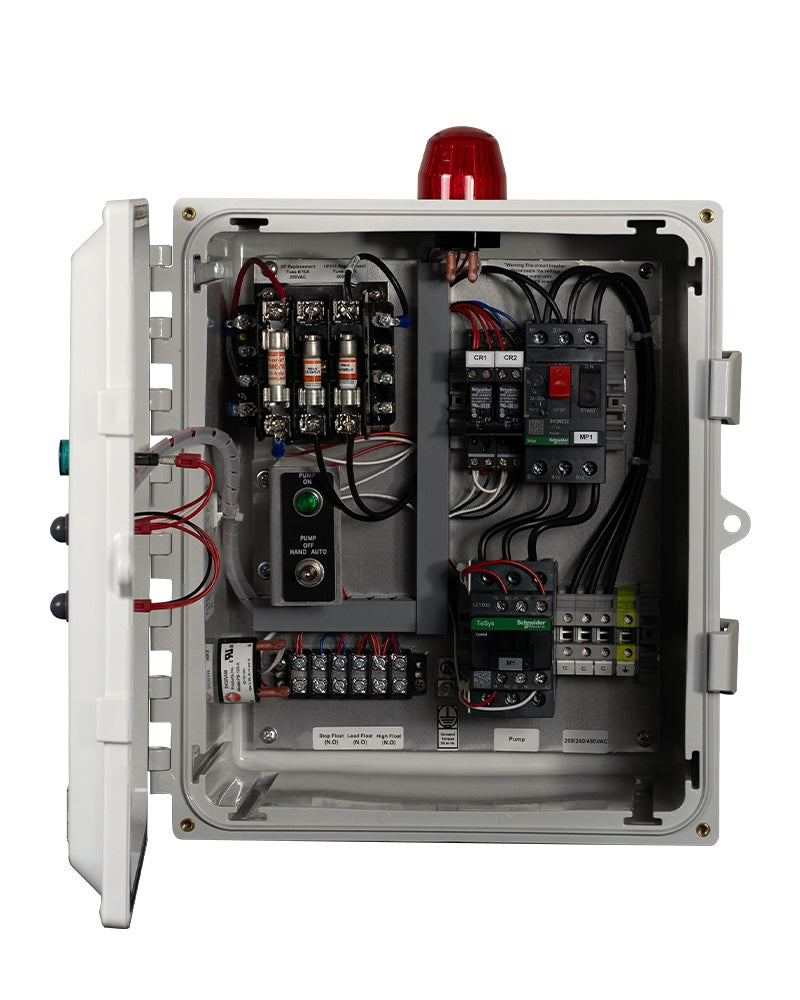

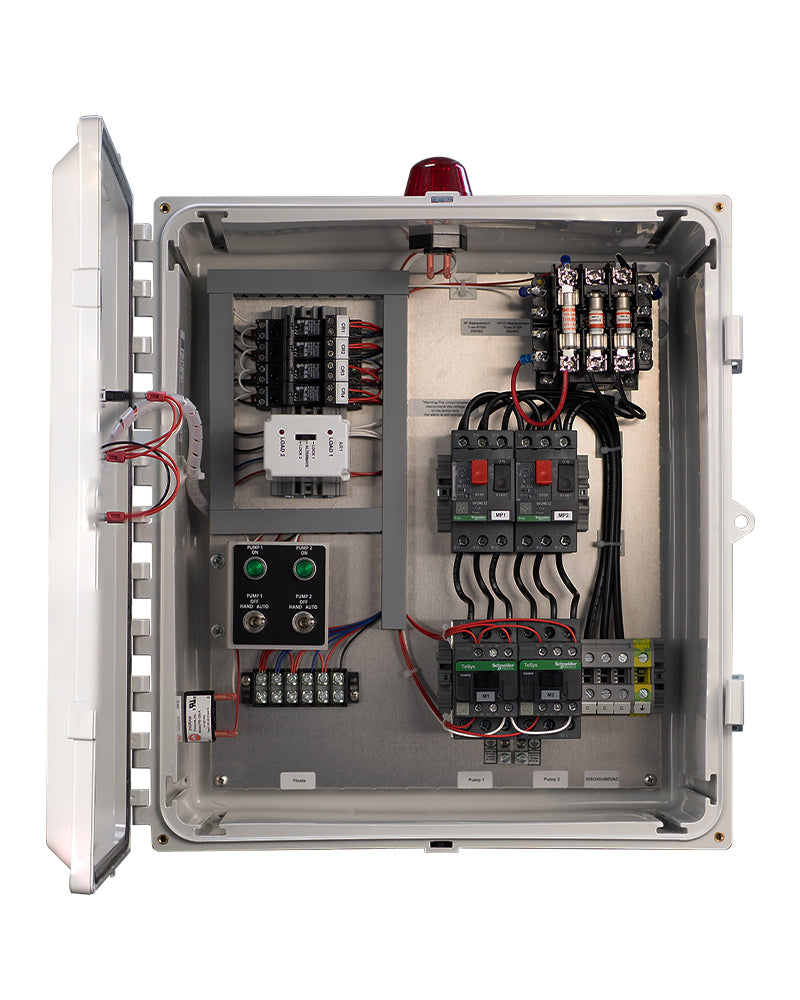

1. Understand the Control Panel’s Components

Before troubleshooting any issue, it’s important to familiarize yourself with the installation brochure, schematic and layout as well as the internal components of the control panel.

Common components found in these panels include:

-

Printed Circuit Board (PCB) & Programmable Logic Controller (PLC): The "brain" of the system, which executes the control logic.

-

Circuit Breakers and Fuses: Protect electrical components from power surges or overloads.

-

Relays and Contactors: Switches that control the operation of equipment like pumps or motors.

-

VFDs (Variable Frequency Drives): Control the speed of motors, allowing for variable flow rates.

-

Sensors (Level, Pressure, Flow): Provide real-time data to the system, which helps the PLC decide actions like turning a pump on or off.

-

Display Panel: Often contains indicators or a digital display showing the status of the system.

2. Ensure the System is Powered On

The first step in troubleshooting is ensuring the system is receiving power. Check for the following:

-

Main Power Switch: Ensure the panel is turned on. Some panels have a master switch to activate the entire system.

-

Circuit Breakers: Inspect all circuit breakers in the panel to verify none have tripped. If a breaker is tripped, reset it and observe if the system resumes normal operation.

-

Fuses: If the circuit breakers are intact, check the fuses to see if any need replacing. A blown fuse can disrupt power to critical components.

3. Inspect for Visible Damage or Faults

Once power is confirmed, visually inspect the control panel for any signs of damage. Look for:

-

Burn Marks or Scorched Components: Indications of overheating or electrical shorts.

-

Loose Wires: Inspect the wiring for any signs of disconnection or wear. Loose or corroded connections can cause intermittent issues.

-

Burned-out LED Indicators: If any lights are not illuminated as expected, they may indicate a malfunctioning component or failed circuit.

4. Check the Status of the PLC

The PLC is a vital part of the control system, and it’s responsible for executing the programmed logic based on sensor data. When troubleshooting, pay attention to the following:

-

PLC Indicators: Ensure the PLC’s indicator lights are functioning correctly. Most PLCs have status LEDs that indicate if they’re operating normally or encountering an error.

-

Error Codes: Some control panels are equipped with a display that will show error codes if there’s a problem. Refer to the manufacturer’s manual to decode the error.

-

Rebooting the PLC: If the PLC is unresponsive or showing an error, try rebooting the system. Sometimes, this can clear any minor glitches and allow the system to function properly again.

5. Test Sensors and Inputs

Many wastewater control panels rely on sensors (such as level, pressure, or flow sensors) to monitor the system’s condition. If a sensor fails or malfunctions, it could send incorrect data to the PLC, leading to operational issues. To troubleshoot sensors:

-

Check Sensor Wiring: Ensure all sensor connections are intact and properly wired to the control panel.

-

Verify Sensor Output: Use a multimeter to test the output from sensors. Depending on the type of sensor (analog or digital), you should see a corresponding voltage or signal that indicates its proper function.

-

Calibrate Sensors: Over time, sensors can lose their calibration. Check if the sensor readings are accurate by comparing them with manual measurements.

6. Examine the Outputs (Pumps, Motors, and Valves)

If the control panel is not properly operating its connected devices—such as pumps, motors, or valves—it’s essential to test these outputs:

-

Manually Operate Equipment: Some panels have manual override options that allow you to manually start or stop pumps and other devices. Test whether the equipment responds to these manual commands.

-

Check Relays and Contactors: Relays and contactors are responsible for switching devices on and off. Ensure they’re operating correctly and that no faults are preventing the equipment from being activated.

-

Inspect Motors: Verify that motors connected to pumps or other machinery are receiving power. If a motor is overheating, it could indicate issues with the motor itself, the wiring, or the relay.

-

Test VFDs (Variable Frequency Drives): If VFDs are part of your system, check their settings and ensure they are correctly controlling the motor speed. Malfunctions in VFDs can lead to erratic operation or complete failure of the associated pump.

7. Review the Control Panel’s Programming and Logic

If the system seems to be powered correctly, and the sensors and outputs are functioning properly, the issue may lie in the programming of the control system. In such cases:

-

Check Logic Programming: Review the control panel’s programming logic (usually programmed in ladder logic or function block diagrams). Ensure there are no programming errors that could be causing the system to behave unpredictably.

-

Download and Update Firmware: Some control panels might require firmware updates. Check if the system’s firmware is up-to-date and reprogram it if necessary.

8. Consult the Manufacturer’s Manual

If the above steps don’t reveal the issue, consult the manufacturer’s troubleshooting guide and manual for more specific guidance. Many manufacturers provide helpful troubleshooting charts and procedures that are tailored to their systems.

9. Seek Professional Help

If troubleshooting doesn’t resolve the problem or if you’re unsure about handling certain tasks (like working with live electrical circuits), it’s best to contact a professional. Qualified technicians can quickly identify and address complex issues, ensuring that your system is restored to full functionality.

Conclusion

Troubleshooting a wastewater control panel requires a systematic approach and attention to detail. By first ensuring that power is correctly supplied, followed by inspecting the system components, sensors, outputs, and programming, you can quickly identify and resolve common issues. Always remember to prioritize safety, and when in doubt, reach out to a professional to prevent potential harm or further damage to the system. With the right approach, you can maintain the efficiency and reliability of your wastewater management system for years to come.