By Thomas Kleist

Last updated February 7, 2025

Using IIoT in the Pump Industry

The Industrial Internet of Things (IIoT) connects you to your pumps from anywhere in the world. IIoT enables remote monitoring, centralized control, and data insights for all of your pump stations. With this cutting edge technology becoming more prevalent, learning the basics of IIoT will allow you to implement and work with an advanced control system at your plant or next installation. Advanced monitoring solutions made possible by IIoT also enhance the diagnosis and prevention of equipment failures, providing real-time insights and continuous monitoring.

In this article we’ll discuss how IIoT works, the advantages of using an IIoT platform, and how you can upgrade your existing and future pump control systems with an IIoT platform.

What is IIoT?

The Industrial Internet of Things starts with your pump control system. When designed or upgraded to connect to IIoT, your control system will automatically report to the IIoT platform. The IIoT platform then processes and stores the data for real-time monitoring, data trending, and remote control of your pumping system from anywhere.

With an IIoT platform, you can view data from your panel such as the current liquid level, pump run status, pump run hours, etc. If you have a more specialized system, an IIoT platform can be used to view other system variables, such as flow rates and chemical levels. An IIoT platform can also send automatic notifications for alarms and faults in your system via email, text, and/or phone call. IIoT platforms enable predictive maintenance by providing real-time data and insights, allowing proactive detection and resolution of issues before they escalate.

An IIoT platform also allows you to control your system remotely. You can adjust the hand-off-auto (HOA) switches of your pumps as well as change settings like lead/lag levels and flow rates.

How IIoT Works

An IIoT network consists of three parts: your control system, the IIoT platform, and the IIoT application. Data collected from your pump station is collected by the IIoT platform and readily available for review and analysis, which enhances decision-making and operational efficiency.

Your Control System

A control system that has been designed or retrofitted to connect to an IIoT platform will contain hardware to connect to the internet. A cellular connection is a very good fit for a pumping station; it is inexpensive, reliable, and does not require any data lines to be pulled to the panel. The control system communicates with the IIoT platform through a secure connection using an industry standard and field tested protocol, such as MQTT.

The IIoT Platform

The platform manages the control systems connected and all of the data received from them. Every connection between control systems and the platform is managed and secured by the platform. Each control system receives a configuration from the platform which tells the control system what data to send to the platform. The platform securely stores the data which is visible to the user in the IIoT application. The IIoT platform also sends commands to the control systems when the user changes a setting or updates an HOA switch.

The IIoT Application

The application is the website or mobile app that you interact with. The application provides real-time monitoring and control; real-time alerts via e-mail, text, and/or phone call; error logs; and CSV data exports.

Advantages of IIoT

The IIoT provides multiple advantages for your pumping systems that will increase uptime, reduce maintenance, and decrease costs.

Remote Monitoring

With an IIoT platform, you are able to view and control your pumps from anywhere in the world. You have instant access to stored data and reports wherever and whenever you might need it.

Centralization

All of your pump station management can be centralized to your IIoT platform, regardless of if it’s a single pump station, multiple within the same plant, or pump stations across the whole state. A cellular connection allows easy deployment in remote locations that would be difficult and time-consuming to reach, as well as notifying you when there is an alarm that would otherwise be missed in the remote location. A well-informed maintenance team can respond to these alerts promptly, managing pump stations more effectively and preventing costly failures.

Data Insights

IIoT platforms provide data logging, dashboards, and data export of critical metrics for your pump station. Insights into the performance of your pumps allows for better maintenance and a longer lifespan. Additionally, data insights from IIoT platforms can help improve pump performance by identifying issues early, such as cavitation or seal leaks, ensuring reliable operation and preventing costly disruptions.

Trending, Reporting, and Predictive Maintenance

With increasing government regulations on the quality of wastewater, it is becoming necessary to sense and record factors like PH, temperature, and turbidity of your effluent. When it comes time to make a report, an IIoT platform makes this a breeze with easy CSV exports - all without having to leave your office. Additionally, IIoT platforms can optimize the processes by providing detailed reports and data analysis.

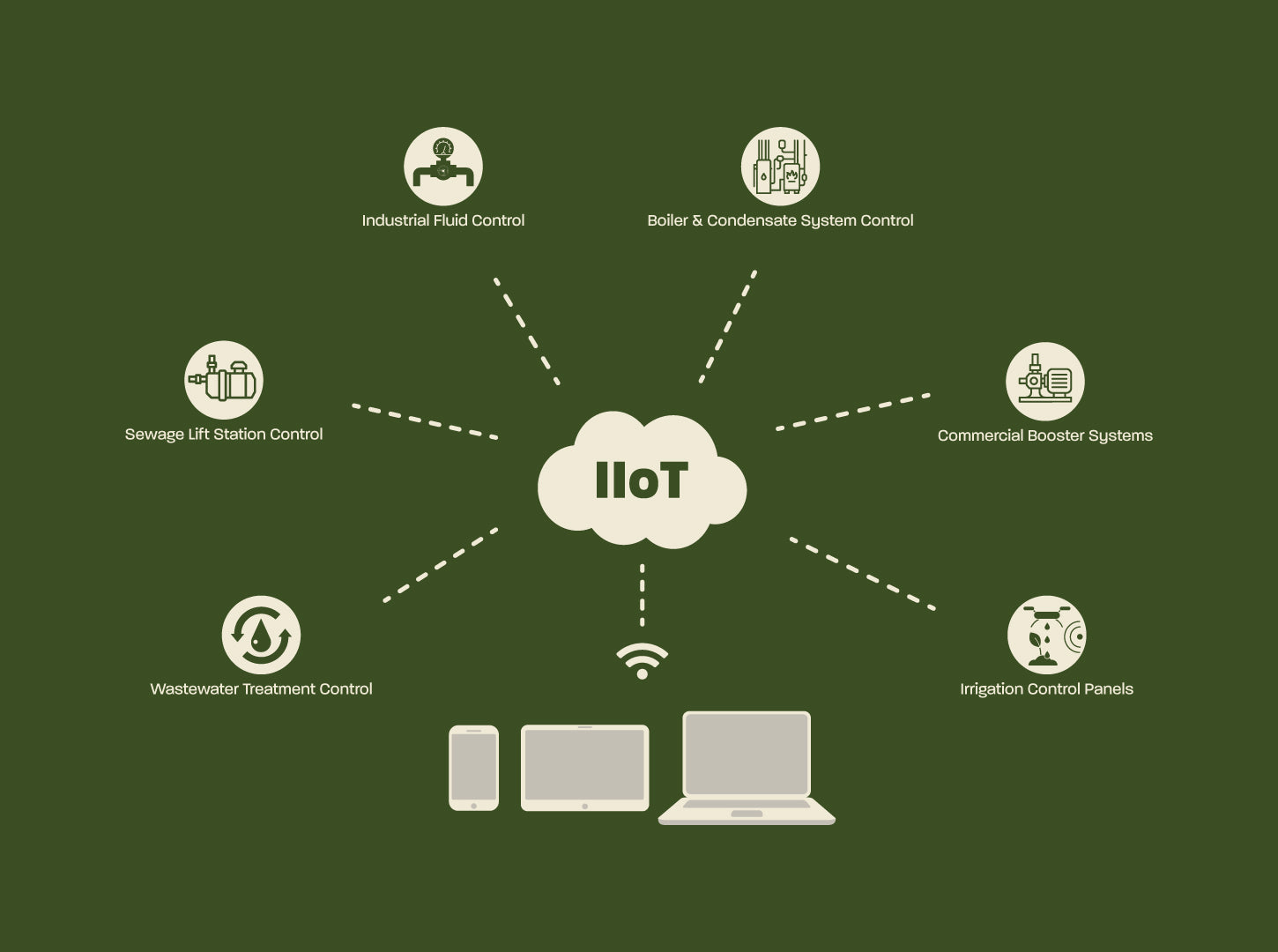

Use Cases for IIoT

There are many use cases of IIoT within the pumping industry. Some applications are:

- Water Pump Control

- Sewage Lift Station Control

- Sewage Pump Chambers

- Sump Pump Control

- Food and Beverage Controls

- Fountain Control Systems

- Industrial Fluid Control

- Chilled Water System Control

- Commercial Booster Systems

- Elevator Sump Control

- Underground Vault Controls

- Fuel and Oil Transfer Systems

- Boiler and Condensate System Control

- Chemical Feed Control

- Wastewater Treatment Control

- Process Fluid Control

- Irrigation Systems

- Application-Specific Electrical Control Panels

How You Can Implement IIoT for Your Control System

Pump Portal®, which is a pump station remote monitoring service offered by See Water Inc., is one powerful IIoT platform that offers all of the capabilities described in this article. Upgrading an existing pre-engineered or custom control system to an IIoT connected system with Pump Portal® is a simple process using a retrofit kit and the dry contacts of your panel.

References

-

"Pump Portal - Remote Pump Monitoring System," See Water, Inc., accessed August 15, 2024

-

"What is the Internet of Things (IoT)?", Amazon Web Services, accessed August 15, 2024

-

"Industrial Effluent Guidelines," Environmental Protection Agency, accessed August 15, 2024

Share:

What is a Radar Sensor?

What is a Pump Control Panel?